The difference between cassava starch and potato starch

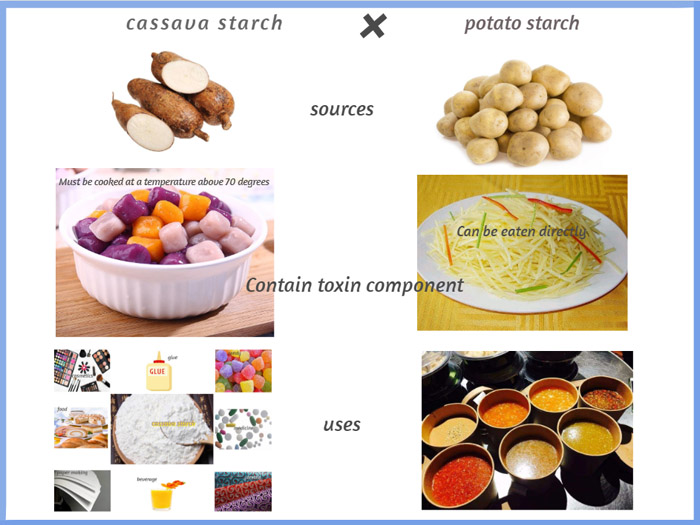

Different sources:

Cassava starch is the starch extracted from cassava, and potato starch is the starch extracted from potatoes.

Contain toxin component:

Cassava starch contains a kind of natural toxin, so it cannot eat raw. The toxin can disappear only when meeting high temperature. Potato starch does not have the presence of this toxin, even if eat raw, also won't have toxic circumstance to happen.

Eating in different ways:

Cassava starch can't be eaten raw because it contains hydrocyanic acid, a natural toxin. The toxin disappears at temperatures above 70 degrees, so cassava starch must be cooked before eating. There is no natural toxin in potato starch, so even if eaten raw, there is no chance of poisoning.

Different uses:

Cassava starch can be used to produce alcohol, fructose, glucose, maltose, monosodium glutamate, beer, bread, biscuits, shrimp chips, vermicelle, sauce and plastic fiber plastic film, resin, paint, adhesive and other chemical products.

As a good thickening agent, potato starch is widely used in sauce food. The use of modified starch can reduce the production cost. At the same time, because the quality of the sauce is stable, it can be stored for a long time without layering, making the product appearance shiny and delicate taste.

The difference between cassava starch and potato starch

The difference between cassava starch and potato starch

Different processing techniques:

Their processes are the same: cleaning, grinding, screening, refining concentration, dehydration, drying. But cassava and potato have different textures, the way they extract starch and the machines they use to process them have subtle differences.

Cassava and potato are cleaned with dry sieve at the beginning of processing. However, as the outer skin of potato is thinner than that of cassava, in order to better protect raw materials, potatoes are washed with rotary washing machine while cassava is washed with paddle washing machine during secondary washing.

Then, in the grinding, screening, refining and concentration process, they all need to use cutting machine and rasper, centrifugal sieve and a fine fiber sieve, disc separator and hydrocyclone.

Because cassava and potato starch granules differ in size and water content requirements, they use different dehydration machines during processing. Cassava starch is dehydrated by a peeler centrifuge and potato starch is dehydrated by a vacuum filter.

Cassava and potato starch use different washing machines and dewatering machines

Cassava and potato starch use different washing machines and dewatering machines

Other differences:

Cassava starch has no peculiar smell, flat taste and no aftertaste. Potato starch has the taste of potato and can retain moisture.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others