Complete set of cassava processing machine

Specifically, the complete set of cassava processing machine is the equipment for processing cassava into different products according to the needs of customers. Cassava processing products include cassava starch, cassava flour, garri and so on. This article will focus on compplete set of cassava processing machine for starch processing.

Here are the introduction of complete set of cassava processing machine for starch processing:

First, dry sieve, paddle washing machine. The most basic equipment in complete set of cassava processing machine is the cleaning & washing machine. The role of these two cassava processing machine is mainly to remove the sediment from the outer surface layer of the cassava and wash away the epidermis of the cassava root. Efficient cleaning machine can effectively clean the impurities of cassava, prevent the dirt and sand impurities from entering the subsequent separation step and improve the quality of starch. These equipment runs smoothly, the cassava breakage rate is low, and the washing effect is good.

Cassava processing machine for cassava cleaning and washing

Cassava processing machine for cassava cleaning and washing

Second, cassava cutting machine and rasper. Cassava starch production line uses these equipment for cassava crushing. Rasper is one of the most important equipment for complete set of cassava processing machine. Its function is to destroy the tissue structure of the cassava, so that the starch granules in the cassava cells can be smoothly separated. DOING rasper is designed by our engineers on the basis of absorbing international advanced technology, featuring with high breaking rate is (higher than 94%) and high starch yield.

Third, starch special washing and separating sieve. Centrifugal sieve and fine fiber sieve are the main parts of complete set of cassava processing machine for starch fiber separation. The device uses water as a medium to separate the fibrous impurities contained in the disintegrated cassava slurry under the action of centrifugal force. The device has good screening effect, the screen is not blocked, the processing amount is large, and the energy consumption is low.

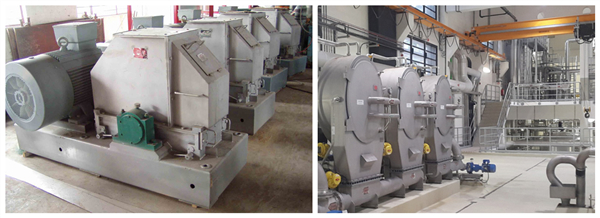

Rasper and centrifugal sieve

Rasper and centrifugal sieve

Fourth, the sand remover and hydrocyclone station. Since the density of sand is greater than the specific gravity of water and starch granules, according to the principle of separation, the method of swirling sand removal can effectively remove the gravel in the starch and improve the taste and economic benefits of the starch. As another important paart of complete set of cassava processing machine, hydrocyclone station is an internationally advanced starch extraction device that integrates concentration, refining and recycling into one. The device adopts fully automated internal design, computer control, reasonable design, beautiful and durable, high efficiency and stable operation.

Sand remover and hydrocyclone station

Sand remover and hydrocyclone station

Five, peeler centrifuge and airflow flash dryer. Peeler centrifuge is mainly used in starch dehydration step before the starch is dried. Its material is stainless steel, which ensures the starch will not be polluted and it has good dewatering effect. Flash dryer as a part of complete set of cassava processing machine is then used for starch drying. The starch dryer is mainly used to remove the moisture of the starch material to achieve the standard dryness of the powder for packaging or use. The efficiency of the flash dryer can be completed in a few seconds, the processing volume is large, and the starch moisture is uniform.

Cassava starch dehydration, drying and packing machine

Cassava starch dehydration, drying and packing machine

Packaging machine: The last one of the complete set of cassava processing machine, which is mainly to automatically package the cassava starch for storage and transportation according to the requirements. It has the characteristics of high degree of automation and labor saving.

Operation Tip of complete set of cassava processing machine: Professional cassava processing machine manufacturers remind people not to contact the rotating parts of the machine to prevent accidents. Electrical equipment (including electric wires) should be inspected frequently for the degree of insulation and comply with the relevant standards. When repairing the equipment, a sign should be placed on the main gate to avoid undue accidents.

Cassava processing machine project in Tanzania

Cassava processing machine project in Tanzania

With the development of science and technology, the improvement of starch-related technology, the market demand for starch quality is getting higher and higher, so the requirements for complete set of cassava processing machine have also increased. The new complete set of cassava processing machine used in DOING cassava starch production line not only precisely controls each production step, but also features fast installation, compact structure, simple operation, high starch quality and high economic efficiency. Moreover, it is not necessary to invest in large-scale environmental protection processing equipment, and the discharged process water is irrigated on the farmland, which is an ideal equipment for the starch production industry.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China