Cassava starch production equipment

In the different section of cassava starch prodcution line, the cassava starch production equipment will have different effects, so here are nine sections in the whole prodcution line.

(1) Conveying / loading

The cassava is sent to the trough and pumped to the stone remover where the stone and other heavy objects are separated, the cassava starch production equipment is the primary cleanup role.

Cassava starch production equipment

Cassava starch production equipment

(2) Cleaning equipment

In order to achieve a better cleaning effect, the secondary cleaning machine of cassava starch production equipment is required. The washed cassava is then transported to the temporary hopper via a tilt belt conveyor.

(3) Unloading spiral

The specially designed discharge port is attached to the discharge conveying screw. The speed of the discharge screw is not adjustable, so the production capacity of the cassava starch production equipment can be fitted by this screw. The outlet of the conveying screw is attached to the honing machine.

Cleaning and washing machine

Cleaning and washing machine

(4) Rasping equipment

Since the rasping efficiency is critical to the overall yield of the system, the cassava starch production equipment is specifically designed to reach the highest efficiency. Europe advanced accessories are introduced by Doing Group to improve the starch extraction rate of the equipment.

Rasper

Rasper

(5) Sand removal equipment

The cassava starch emulsion from the rasping machine is conveyed by a screw pump to a sand removing cyclone to remove sand. The working principle of this cassava starch production equipment is specific gravity separation.

(6) Fiber extraction equipment

The starch emulsion from the sand removing unit is sent to the extraction unit, and the extraction unit is integrated, including three conical rotating centrifugal sieves, a fiber pump, and a defoaming pump. The fibers are washed and divided in a countercurrent manner by the cell fluid from the multistage cyclone in this 3-stage sieve. The separated fibers enter cassava starch production equipment dewatering screen for dehydration.

Centrifugal sieve

Centrifugal sieve

(7) Refinement equipment

The starch milk from the first stage centrifugal sieve enters a 16-stage concentrated cyclone washing unit, and the process water is pumped from the other end of the cyclone station to wash the starch in a countercurrent manner. The whole cyclone station can consist of three parts. First, the starch milk is dehydrated and concentrated by a focused cyclone station, and the concentrated starch milk enters the subsequent 13-stage washing unit, and the overflowed cell liquid enters the recycling cyclone station. Starch contained therein is recovered. The starch milk from the cyclone station is pumped into a stainless steel cassava starch production equipment.

(8) Starch dehydration equipment

The moisture content of the starch milk coming out from the cyclone station is too large to be directly dried. Therefore, the starch milk should be dehydrated first, so that the moisture content of the starch is about 40%. The working process of this cassava starch production equipment is:

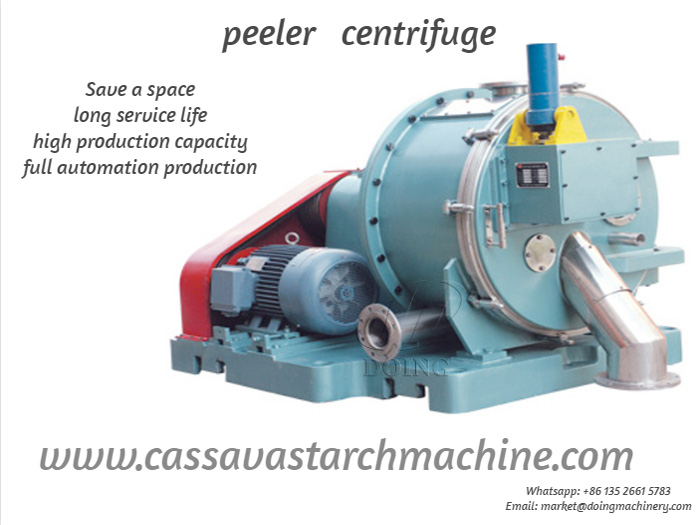

Peeler centrifuge

Peeler centrifuge

the starch pump is pumped from the starch milk temporary storage tank into the vacuum dehydrator tank, and a water pipe is connected to the starch milk pipeline, and the starch milk is diluted to a certain concentration with the process water. The vacuum pump creates a negative pressure in the vacuum drum. When the starch emulsion is in contact with the vacuum drum of this cassava starch production equipment, the starch milk is sucked on the drum surface, the filtrate is sucked into the filtrate separation tank and pumped away from the filtrate, and the filter cake is scraped off by the scraper. The food-grade conveyor belt is used to transport the feed hopper of the intake air dryer.

(9)Starch drying equipment

The final cassava starch production equipment is flash dryer whose main function is to dry wet starch to a moisture content of 14%.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour