How to make tapioca starch from cassava?

Tapioca starch is mainly used as raw materials in food, sugar, medicine, feed, textile, paper, chemical and other industrial sectors. The tapioca starch production process is a physical separation process, that is, separating the starch in the raw material from other substances such as fiber, inorganic matters and the so on. In the production process of how to make tapioca starch from cassava, according to the properties of starch is insoluble in water and the specific gravity of the starch, water and special mechanical equipment are used to separate the starch from the water suspension, thereby achieving the purpose of recovering the starch.

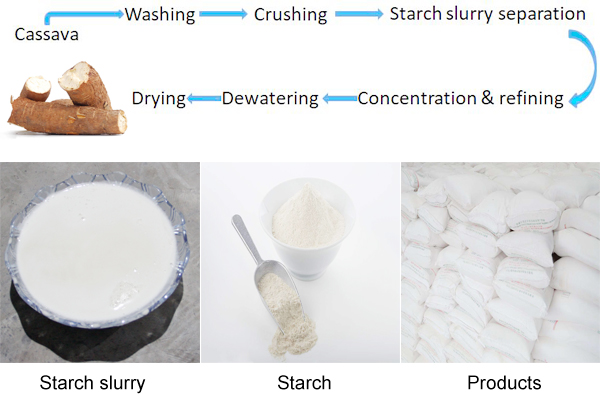

The production process of how to make tapioca starch from cassava is divided into the following part:

Weighing and conveying, cleaning, washing, grinding, separation, desanding, concentration and refining, dehydration, starch drying and packaging processes.

How to make tapioca starch from cassava

How to make tapioca starch from cassava

Unit 1.Raw material weighing and conveying

Due to the short storage time of cassava roots, it is essential to complete the entire process of how to make tapioca starch from cassava as soon as possible. The newly harvest cassava is firstly weighed by the weighbridge and stored in the cassava yard for storage. Then the weighted cassava is transported by a belt conveyor to cleaning machine for processing.

Unit 2. Cassava cleaning

Then it's time for the cleaning, which receives the raw material via belt conveyor. The machine used for cleaning is dry sieve whose main function is to remove the stone, weeds and other objects for the process of how to make tapioca starch from cassava. After that the cassava enters the washing process.

Unit 3. Cassava washing

After cleaning, the cassava is transported into paddle washing machine where the mud, dirt, soil and the skin of the cassava are removed. After the two process of cleanings and washing for how to make tapioca starch from cassava, the mud, sand and other impurities on the surface of the cassava have been basically removed, and the outer peeler are roughly removed.

Tapioca washing machine

Tapioca washing machine

Unit 4. Cassava grinding

In the processing of how to make tapioca starch from cassava, it is vital to release as much as free starch from cassava roots as possible. For the more free starch is obtained, the more starch yield is gained. Therefore grinding plays a vital role in the cassava yield. Rasper is the widely used cassava grinding machine whose main function is to destroy the structure of the cassava, so that the tiny starch granules can be released from the roots of the cassava.

Unit 5. Starch slurry and residue separation

The separation unit is the next step of the how to make tapioca starch from cassava, and the used machine normally comprises centrifuge sieve and fine fiber sieve. The main function of this process is to separate the fibers out of starch slurry. After this process, the starch has reached the commercial standard of finished product in terms of fineness.

Tapioca starch refining machine

Tapioca starch refining machine

Unit 6.Starch slurry desanding

The handling of the starch in this stage is mainly for removing sand out of starch slurry so as to improve the starch taste for how to make tapioca starch from cassava. Desander takes use of density separation method achieving the sand removing purpose.

Unit 7. Concentration and refining

The starch slurry after desanding process still contains organic and inorganic impurities such as protein, cell sap and so on, which need to be further processed for how to make tapioca starch from cassava. Hydrocyclone station is used for this purpose. Full hydrocyclone technology can achieve the concentration, refining and recycling of starch.

Tapioca starch drying machine

Tapioca starch drying machine

Unit 8. Starch milk dehydration

The function of this process for how to make tapioca starch from cassava is to reduce water content of starch slurry to meet the requirements of drying. Peeler centrifuge is a high efficient machine used for starch dehydration. After dehydration, the water content is about 38%-40%.

Unit 9. Starch drying and packing

The starch undergoes thorough drying process to meet the requirements of the commercial product for the process of how to make tapioca starch from cassava. After drying, the water content is about 14%.Then it is packed by semi-automatic packing machine for for marketing.

This is the entire process for how to make tapioca starch from cassava. Doing Company is a professional cassava starch processing machine manufacturer, we can provide you with complete services including design, manufacture, installation, commissioning and personnel training. Welcome to contact our engineer for tapioca starch processing machine.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour