How to dry cassava starch for processing cassava into starch?

It has long time storage when the moisture content of cassava starch was controlled around 13.5%-14%. So drying cassava starch is necessary and important. The following is two methods to dry cassava starch for processing cassava into starch.

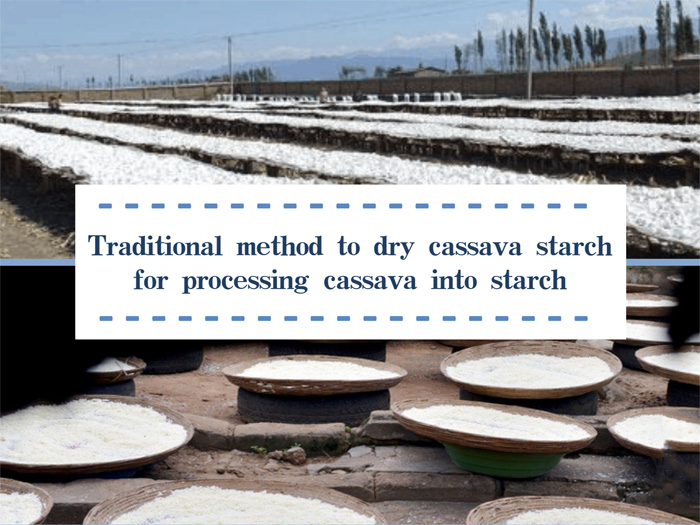

The one is traditional method. The pure starch milk should be deposited. And then remove the water to get a cassava starch cake. Next dry the starch under the sun. Or if people want to dry the cassava starch quickly, you can use two fans to blow the wind and the outside starch will fall down when moisture is less. By this method, it will not affect the quality of cassava starch.

The traditional method is mainly used for small capacity cassava starch production or home use. It is time-consuming but saves cost.

Traditional method to dry cassava starch for processing cassava into starch

Traditional method to dry cassava starch for processing cassava into starch

The other one is the newest cassava starch processing technology which need be equipped with a flash dryer. After dewatering the cassava starch, the moisture is normally around 38% ~ 40%. The hot wind of our newest cassava starch flash dryer is around 20m/s. It can ensure the moisture of dried cassava starch is around 13.5% ~14% within 2 seconds. If the capacity of cassava starch is larger, it is essential to match a flash dryer. With the flash dryer drying, the final cassava starch whiteness shall be better than traditional method and can ensure a continuous processing and packaging.

Flash dryer to dry cassava starch for processing cassava into starch

Flash dryer to dry cassava starch for processing cassava into starch

You can choose suitable method according to your capacity. If you have a large capacity of cassava starch processing, welcome to contact us to get more information about flash dryer.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour