Which cassava starch dryer is better for drying cassava starch?

As an international export cassava starch processing machine manufacturer, the cassava starch processing machine produced by Henan Jinrui has been exported to more than 80 countries. According to our rich experience in cassava starch processing machine installation projects, the flash dryer is the best dryer for drying cassava starch.

flash dryers is a specialized starch dryer, which is widely used in the drying of powdery materials, such as: cassava starch, cassava flour, potato starch, and sweet potato starch. The moisture content of the cassava starch after being dried by the flash dryer can generally be controlled between 12%-14%. In addition, the flash dryer has other advantages in drying cassava starch.

Flash dryer being installed

Flash dryer being installed

First of all, compared with other cassava starch dryers that use positive pressure drying systems, Henan Jinrui's flash dryer uses negative pressure drying. The operation mode of the flash dryer is to suck cassava starch into the drying tube through the fan at the tail. The pressure inside the drying tube is small, and the pressure outside the tube is high, so cassava starch loss will not occur during the operation of the flash dryer. And we have an explosion-proof device at the top of the flash dryer, which is used to relieve pressure and explosion . However, the cassava starch dryer with positive pressure drying has high pressure inside the drying tube and low pressure outside the tube, which can easily cause cassava starch loss.

Operation process of flash dryer

Operation process of flash dryer

Besides, the flash dryer has an automatic chain control function. The role of this function is that the drying system automatically adjusts the cassava starch feed volume and air intake volume by predicting the moisture content of cassava starch and air temperature, so as to ensure the stability of the water content of the cassava starch. In order to accurately control the temperature, Henan Jinrui has set temperature control points at the air inlet of the flash dryer, the air inlet of the cyclone separator and the exhaust duct.

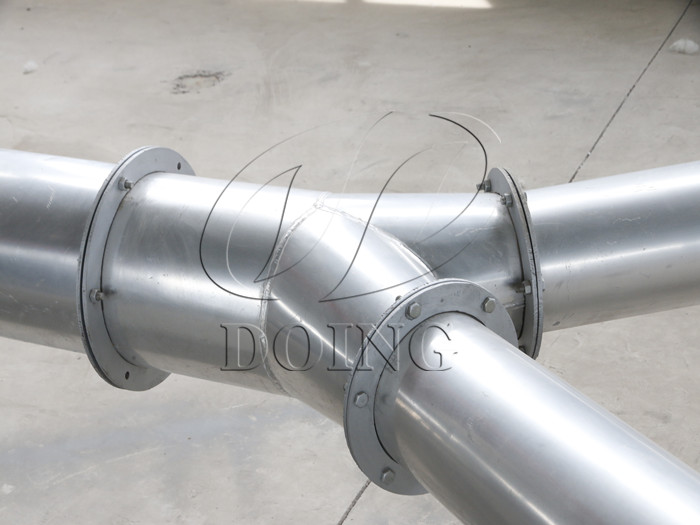

In addition to the above advantages, the flash dryer is made of 304 stainless steel, which effectively prevents the machine from being corroded by cassava starch and prolongs the service life of the flash dryer. Moreover, the operation speed is fast, the energy consumption is low, and the processing capacity is large.

Stainless steel tube of flash dryer

Stainless steel tube of flash dryer

If you are looking for a more efficient cassava starch dryer, please contact Henan Jinrui. We will provide you with more information about the flash dryer, and customize it for you according to your production needs.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others