Sweet potato starch processing plant

Modern sweet potato starch processing plant usually use professional sweet potato starch maachine, using the physical properties of sweet potato starch, crushing sweet potatoes, separating impurities such as fibers and proteins, and dehydrating and drying starch to obtain edible sweet potato starch.

The specific processing flow of sweet potato starch processing plant includes the following steps: raw material receiving - quantitative conveying cleaning machine - cage washing machine - rasper - centrifugal sieve - fine slag screening - sand remover - concentrated refining hydrocyclone station - Vacuum dewatering machine - Airflow flahs dryer - Automatic packaging machine

Sweet potato starch machine

Sweet potato starch machine

First the sweet potato need to be cleaned. Different from the traditional time-consuming and laborious hand washing method, the modern sweet potato starch processing plant generally uses a variety of cleaning machinery to remove the impurities on the surface of the sweet potato to ensure the starch taste and purity in the subsequent production process.

Then sweet potato need to be crushed to release starch in sweet potato starch processing plant. The raw sweet potato is pulverized and ground by using a professional crushing machine to release the starch located in the cells. The more thoroughly the starch material is pulverized, the more thoroughly the starch is freed, and the higher the starch extraction rate as well ad the higher the starch yield.

Next step in sweet potato starch processing plant is starch slurry screening and filteration. The pulverized starch slurry is subjected to primary filtration for the purification of starch to remove impurities such as fibers in the starch slurry.

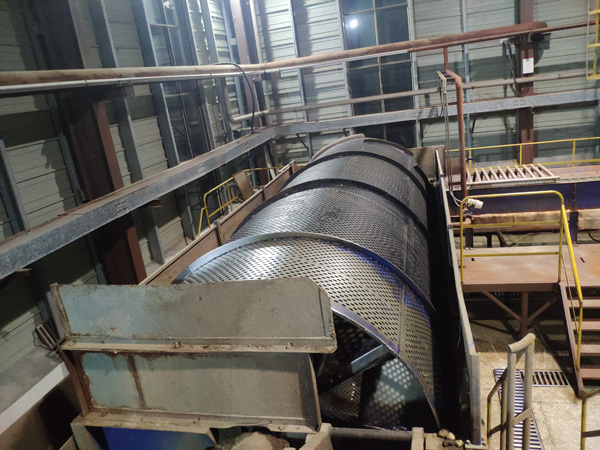

Sweet potato cage washing machine

Sweet potato cage washing machine

Then the sand content in starch slurry need to be removed. In sweet potato starch processing plant, sand removal serves to remove the sand which affects the taste of starch slurry. The basic quality of the starch is ensured by sufficiently removing the fine foreign particles in the starch.

Then is the starch slurry concentration, refining and recycling process. DOING sweet potato starch processing plant uses advanced hydrocyclone system to separate most of the non-starch substances such as fine fiber, protein, yellow powder, oil powder and pectin in starch slurry to improve the whiteness and quality of starch.

Sweet potato starch refining machine

Sweet potato starch refining machine

Refined starch milk need to remove extra water content to faciliate drying in sweet potato starch processing plant. Vacuum filter takes use of negative pressure for water dehydration, characteristized with high dehydration rate of starch. It can effectively improve the purity of starch, the starch after dehydration is easy to dry, and the quality of finished starch is guaranteed.

After the dehydration of the wet starch, sweet potato starch processing plant need to dry starch to obtain desired quality starch. The use of high-strength starch flash dryer quickly remove surface water of starch, featuring with low temperature and high air volume, fast drying speed, no contact with the outside world, no pollution.

Sweet potato starch drying machine

Sweet potato starch drying machine

Then it comes to the last step in sweet potato starch processing plant - finished starch packaging. Using automatic packing machine packs the processed starch into bags to avoid corrosion, ensure hygiene and facilitate transportation.

As an adaptable crop, sweet potato is widely planted all over the world. Sweet potatoes can not only be eaten as food but also be made into starch. The processed starch can be further used as an industrial raw material for medicine, food, chemical industry, etc., and can also be used as a new type of power energy raw material and feed. With the development of industrialization, changes in consumption structure and market structure, starch processing has become the main processing channel of sweet potato industry in recent years. The demand for sweet potato starch is huge, and the processing prospect of investment in sweet potato starch processing plant is considerable.

Sweet potato starch processing plant

Sweet potato starch processing plant

Doing Company is a company specializing in starch processing projects, we can provide customers with different types and configurations of starch plant production lines according to the actual processing volume and investment budget of processing users. The daily processing capacity of different types of starch production lines is also different. DOING production lines of sweet potato starch processing plant are: simple production line, economic production line, practical production line and standard production line. If you are interested in the sweet potato starch plant project, please contact us.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China