Home > product > Cassava starch processing machine > Cassava starch processing machinery manufacturer

Cassava starch processing machinery manufacturer

Doing Company is a professional cassava starch processing machinery manufacturer, the cassava starch manufacturing process of our company is divided into the following section:

Cassava cleaning-washing-crushing-starch screening-concentration and refining-dewatering-drying and packing

As a cassava starch processing machinery manufacturer, we can provide complete set of cassava starch processing machinery for this process

Dry sieve-paddle washing machinery-rasper-centrifuge sieve, fine fiber sieve-hydrocyclone station-peeler centrifuge-flash dryer and semi-automatic packing machinery

Cassava starch processing line

Cassava starch processing line

1. Dry sieve for cassava cleaning: Dry sieve is used to remove sand, soil, skin and starch ash from cassava roots. This machinery features with large capacity and low power consumption. As a cassava starch processing machinery manufacturer, we can design the appropriate parameters of the machinery to satisfy your need.

2. Paddle washing machinery: Cassava starch processing machinery manufacturer usually design this machinery by adopting countercurrent method to achieve better washing effect. The capacity of this machinery can also be customized according to requirements.

3. Rasper for cassava crushing: Rasper is an important machinery in cassava starch manufacturing process which determine the starch yield. Therefore the cassava starch processing machinery manufacturer introduce the international advanced technology to design and manufacture this machinery. DOING rasper is such an achievement based on advanced EU technology and extraction rate up to 95%.

4. Cassava starch screening machinery: The used machinery for starch screening includes centrifuge sieve and fine fiber sieve. They are mainly used for separating fiber and starch. As a cassava starch processing machinery manufacturer, our starch screening machinery has the features of good screening effect, low energy consumption and low cost.

Cassava starch processing machinery

Cassava starch processing machinery

5. Hydrocyclone station for starch concentration and refining: Hydrocyclone station uses: to concentrate and refine and recycle starch. To achieve multiple functions such as concentration, recovery, washing and protein separation, cassava starch processing machinery manufacturer usually design multi-stage cyclone for cassava starch manufacturing process.

6. Cassava starch dewatering machinery: The function of dewatering machinery is to decrease water content in cassava starch to reach the standard of starch drying. The used machinery can be peeler centrifuge sieve and vacuum filter. Traditional cassava starch processing plant only use peeler centrifuge for starch dewatering. As an advanced cassava starch processing machinery manufacturer, Doing Company combines the two machinerys together which is more efficient.

7. Cassava starch drying and packing machinery: Drying machinery is used for drying wet starch to the meet market standard. Flash dryer is the widely used starch drying machinery. As a cassava starch processing machinery manufacturer, this machinery is designed with stainless steel material which can effectively prevent the starch from polluted. The semi-automatic packing machinery can also be designed and manufactured according to demands.

Cassava starch processing machinery manufacturer

Cassava starch processing machinery manufacturer

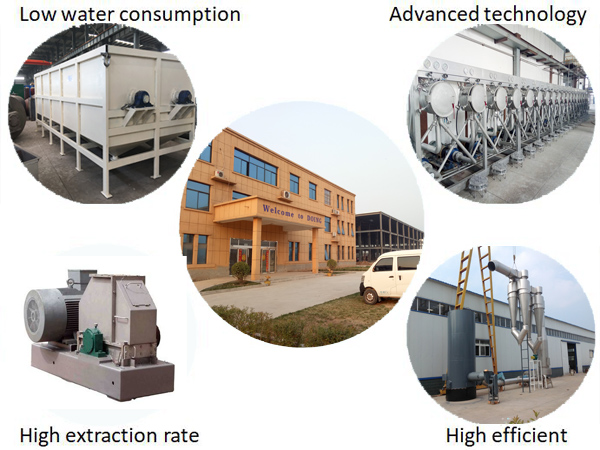

As a cassava starch processing machinery manufacturer, our cassava starch processing machinery features with:

1. Low water consumption: cleaning water 1:4.

2. High starch extraction rate and high rasping rate: more than 95%

3. Advanced technology: As a cassava starch processing machinery manufacturer, our rasper introduces the advanced Sweden SKF bearing and Germany Optibelt.

3. High efficient separation: The primary slurry is passed through a sieve hole of about 8.0 mm.

Features of cassava starch processing machinery

Features of cassava starch processing machinery

4. The second starch slurry puree passes through about 1.2 mesh.

5. By screening and washing, starch content in the starch residue is less than 35%, wherein the free starch contains less than 5%; the fiber impurity content in the starch milk is less than 0.05%.

6. As an advanced cassava starch processing machinery manufacturer, our hydrocyclone station adopts advanced European technology which ensures the final cassava starch meet European standards.

6. After dehydration, the moisture content of the wet starch is less than 38%.

7. The finished starch has a water content of about 13.5%.

As a experienced and senior cassava starch processing machinery manufacturer, Doing Company can provide professional and advanced cassava starch processing machinery according to different requirements.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour