Economic importance of cassava starch production

Cassava production countries should increasingly convert this relatively low-cost raw material into high-value starch for domestic and international markets.

It is estimated that 60 million tons of starch is extracted annually from various cereal, root and tuber crops which is used for surprisingly diverse products: stabilizers for soups and frozen foods, coatings for tablets and paper, stamps and plywood adhesives, hardeners for textiles, raw materials for making ethanol, and even as binders for concrete. 10% of this type of starch comes from cassava roots, a more well-known crop and the staple food for millions of low-income rural people in Africa, Asia and Latin America.

Cassava starch usage

Cassava starch usage

With the current annual production of cassava roots in the world reaching about 200 million tons, FAO confirms the economic importance of cassava starch production, believing that by converting relatively inexpensive raw materials into high-value starches, many developing countries can strengthen their economies and increase the income of cassava growers. Danilo Mejía is an agricultural engineer in the FAO, who said: "The cassava can make very good starch. Compared with the starch from most other plants, cassava starch has better transparency and viscosity, it is very stable in acidic food products. It also has good properties of non-food products such as pharmaceuticals and thermoplastic biodegradable plastics."

Cassava starch production is a very competitive. As a crop, cassava has advantages in production, such as high yield per unit area, drought tolerance and adaptation to poor land, and great flexibility in planting and harvesting. It is highly competitive as a source of starch: its roots contain more starch than almost any other food crop on a dry weight basis, and starch is easily extracted using simple techniques. Export prices are always lower than those of potato, corn and wheat starch produced in the EU and the US. For example, the premium tapioca starch produced in Thailand currently sells for about US$225 per ton.

Cassava and cassava starch

Cassava and cassava starch

As a program promoted by IFAD and FAO, the Global Cassava Development Strategy recognizes the importance of processing fresh roots within a market-driven commodity chain to produce by-products such as starch. However, although global demand for cassava starch has increased over the past 25 years, it is only in Thailand that cassava has completed the conversion of staple foods to industrial processing products and raw materials.

In Africa, with an annual output of more than 100 million tons of roots, there is almost no starch extraction industry except Nigeria and South Africa. “In most countries in tropical Africa, cassava root is a basic staple food, an important reserve for other crop failures and an increasingly economic crop for the urban market, "NeBambi Lutaladio, an expert on root and tuber crops at FAO's crop and pastures said. "Although the starch imported by some countries can be produced locally using cassava, its government has not been able to adjust its policies to encourage the cassava starch production. "There is no tradition of public research and development of tapioca starch value-added production

"In addition, there is no tradition of public research and development in value-added cassava starch production, and the private sector is reluctant to invest in research to improve cassava starch processing technology due to lack of patent protection." In countries where a certain amount of starch extraction activity is carried out, due to inconvenient transportation and insufficient power supply and lack of well-trained personnel, their cassava starch production efficiency is not high and therefore lacks global competitiveness.

Cassava starch production technology

Cassava starch production technology

Building a modern cassava starch processing plant typically requires $8-10 million in capital and a large amount of additional funds to cover operating expenses for the first few years. At present, private investors lose interest in investment because of the fact that many African farmers use unmodified cassava varieties, the quality of the starch produced is low, and the supply is unstable - farmers prefer to sell fresh produce as food when the market price is higher.

Rutaradio believes that a viable starch production industry in Africa "cannot rely solely on small-scale producers. It requires organized contract farming and large-scale planting with high-yield varieties, and is capable of carrying out large-scale raw material processing after harvest and the relevent starch production echnology and solid knowledge about the commodity chain."

In Latin America and the Caribbean, the cassava starch industry is expanding, and high-value improvements and the production of hydrolyzed starch have become a clear trend. However, starch production accounts for only a small fraction of the total production of cassava. It is estimated that 60-70% of the total annual production of approximately 40 million tons of cassava roots in the region is used as a traditional food, and the region accounts for only about 4% of the global supply of cassava starch.

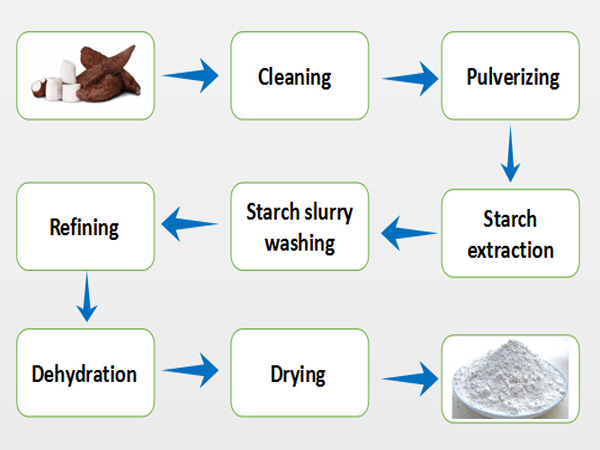

Cassava starch production process

Cassava starch production process

Although large modern processing plants are already operating in Brazil, Colombia and Venezuela, most of the cassava starch production is carried out using labor-intensive traditional techniques in small and medium-sized, community-level plants. While FAO sees the region "a range of opportunities to be siezed in cassava starch production," it also lists many of the serious obstacles facing the industry, including extremely irregular supply and uneven quality of final products.

An example of Thailand shows the economic importance of cassava starch production. FAO believes that in the global and domestic starch markets, the key to the future of cassava is the improvement in efficiency and quality and the reduction in production costs. African and Latin American countries need to look at Thailand, the world's largest producer, to find a successful model for the development of the cassava starch industry. The industry in Thailand began more than 50 years ago and developed rapidly in the 1990s, when trade restrictions drastically reduced the market for Thai dried cassava chips used as livestock feed in Europe.

The core of a government-sponsored cassava starch project is the introduction of higher yielding cassava varieties from local and Latin American germplasm crosses. By 1996, the area of improved cassava cultivation had reached 380,000 hectares, or one-third of the country's cassava cultivation area, and the current root production was as high as 20 tons per hectare. Thailand now uses about 50% of its annual output of cassava roots, about 18 million tons to extract about 2 million tons of starch. Half of them are supplied to the domestic food and non-food industries, and the rest are exported, mainly in Japan and Taiwan, and more and more are exported in the form of high-value starch, modified starch for specific uses.

Cassava starch processing plant

Cassava starch processing plant

"Thailand has proven its goal through the use of cheap labor, low-cost transportation and efficient sales of products," said FAO's Nebbi Rutaradio. "If more countries see cassava as a strategy and a basic product of industry, it will benefit the development of their food, agriculture and industrial sectors and promote employment in rural and urban areas."

FAO recommends that the emerging cassava starch industry should first focus on meeting the domestic market – a study of the international cassava market found that tropical countries import more than $80 million in corn starch and derivatives per year. The study also found that in many countries, almost all imported products can be replaced with locally produced cassava starch.

In Africa, there is an indication that interest in using native cassava starch as a substitute for imported products is increasing. Uganda, Tanzania and Madagascar have initially established companies for cassava starch production, and many industries in Malawi have expressed interest in purchasing local cassava starch for paper, cardboard, confectionery and food processing. At the same time, Nigeria, a major producer of cassava in the region, recently announced an ambitious plan to use cassava to produce ethanol biofuels.

"In all tropical countries with a certain degree of industrialization, local cassava starch has some degree of market opportunity. However, for new members who may enter this market," said Mr. Nabbi Rutaladeo. they can only succeed if they are adequately funded to support this risk and are able to provide a reliable supply of starch at competitive prices to meet user requirements."

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour