How to make cassava starch?

Cassava root is rich in starch, and fresh cassava contains 20% to 35% starch, protein 1-2%, fat 0.34%, cellulose 1-2%, ash 1%, moisture 60% ~ 80%, which indicates that cassava is a good raw material for starch. But how to make cassava starch? The following is the answer for this question.

Cassava composition table:

| Fresh starch | Contents |

| Starch | 20%-35% |

| Protein | 1%-2% |

| Fat | 0.34% |

| Cellulose | 1%-2% |

| Ash | 1% |

| Moisture | 60%-80% |

Cassava

Cassava

The detail description of the process for how to make cassava starch

Step 1. Transportation and cleaning: The fresh cassava collected in the stockyard is collected through the ground, transported to the cleaning machine by a belt conveyor. In the process of how to make cassava starch, the epidermis of the cassava and stone, weeds and other debris therein are initially removed by stirring in the cleaning machine.

Step 2. Washing: Then cassava enters into the washing process for how to make cassava starch. After washing, the mud, sand, soil and other impurities on the surface of the cassava have been basically removed, and the peeling rate can also reach up to 80%. Although simple in theory, the first two steps are the basis for producing high quality cassava starch.

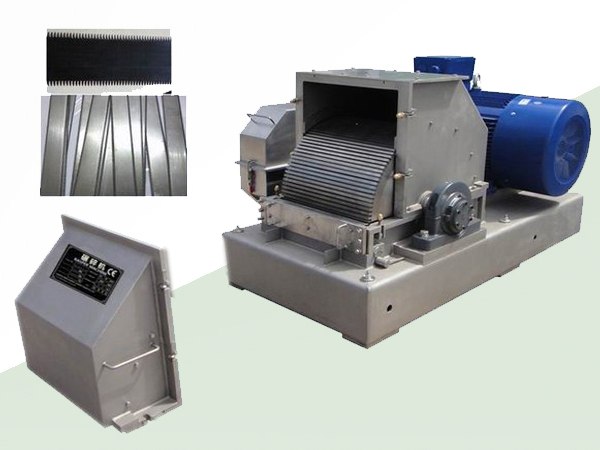

Step 3: Grating: The cleaned cassava is pulverized by a rasper, and the function of grating for how to make cassava starch is to destroy the structure of cassava, so as to make sure the tiny starch granules can be disintegrated and separated from the cassava cells. With water as the medium, the cassava is slurried after grating, and the starch has been substantially freed out and becomes a slurry mixture.

Cassava grating machine

Cassava grating machine

Step 4: Separation: The starch slurry is then pump into a centrifuge sieve for separation. For the process of how to make cassava starch, the slurry mixture is separated by four stages centrifuge sieve, and the separated cassava waste is transported to the slag field. Fine fiber sieve is also used for separate fine fibers out of starch slurry. The refined starch milk has reached the finished product standard in terms of thickness, but there are organic and inorganic impurities such as protein mud, and sand need to proceed by the next step.

Step 5: Desanding: The starch milk is pumped into the sand remover through a starch pump to remove inorganic impurities such as mud and sand. The main function of this process for how to make cassava starch is to improve the taste of final starch for market standard.

Cassava starch separation machine

Cassava starch separation machine

Step 6: Enrichment and refining: The starch milk enters the 18 stage hydrocyclone groups through the starch pump, the main function of the first two stages is to deproteinize, and the second 12 stages are mainly used for concentration and refining, and the residue stages is for washing and recovering. After the above process of how to make cassava starch, the starch milk basically meets the requirements in terms of whiteness.

Step 7: Dehydrating: Peeler centrifuge is adopted for dehydrating. After dehydrating for how to make cassava starch, the water content of the starch is reduced from 60% to 38-40%, and the water in the peeler centrifuge (contain about 1% and 5% of starch) continue to return to the former step for concentration, and then wet starch is sent to the flash dryer for processing through a screw conveyor.

Step 8: Drying: The flash dryer uses hot air to heat the starch to achieve the purpose of drying for how to make cassava starch. The whole system is in a negative pressure state, and features with no dust and energy saving. After the starch is dried, the water content is between 12% and 14%, which is the standard of the finished product.

Cassava starch drying machine

Cassava starch drying machine

Step 9: Sieving and packing: In order to ensure that the fineness of the finished product meets the standard for how to make cassava starch, it is also necessary to pass the finished product vibration sieve to prevent the starch from agglomerating during the drying process, thereby ensuring that the final product meets the standard. After sieving, the starch is then packaged into 25Kg or 50Kg according to the requirements.

In conclusion, the above steps are the detail description of how to make cassava starch. As a professional and experienced cassava starch processing machine supplier, Henan Doing Mechanical Equipment Co., Ltd offers technical design, assembly technology and equipment installation and debugging service. Doing equipments sell well in more than 20 countries and areas, such as Nigeria, Ghana, Malaysia, the Philippines, India, Vietnam, Cambodia, Indonesia, etc.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others