Factors affecting starch yield in cassava starch production line

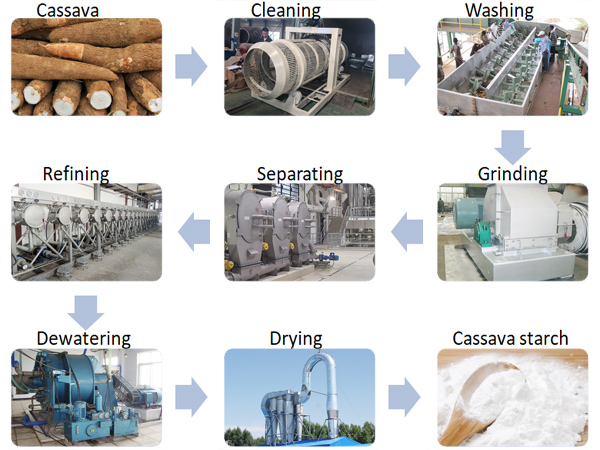

The starch processing technology of cassava can be roughly summarized as: cleaning, crushing, separating, refining, dehydrating, drying, etc. However, in cassava starch production line, the main stages that influence starch yield (starch extraction rate) is crushing and separating stage. For drying stage, as long as temperature is controlled in reasonable range and the dry weight of the starch and the water content reach standards, it has little effect on the extraction rate of starch. Below we will specifically analyze the impact of these links on starch yield in cassava starch production line.

Cassava starch production line

Cassava starch production line

Crushing stage

Crushing is the most influential part for starch yield during the cassava starch production line. Because the main purpose of crushing is to break the tuber cell wall of raw cassava as much as possible, so that the starch particles can be extracted. The higher the cassava breakage rate, the higher the starch yield. Therefore, in order to increase starch yield in cassava starch production line, the starch extraction efficiency must first be improved.

Commonly used cassava crushing machine include hammer crusher and rasper. Compared with the hammer crusher, the grinding machine is the most efficient cassava grinding equipment at present. The rasper has higher pulverization efficiency and higher starch extraction rate, so the starch yield is also higher. In particular, the rasper from Doing Company not only has advanced equipment technology, but also introduces European accessories such as German Optibelt and Swedish SKF bearing, and the equipment has a longer service life. Therefore, for large-scale or most production-oriented cassava starch plants, the selection of high efficient rasper is the key to increasing cassava yield in cassava starch production line. However, the price of rasper is relatively expensive. Therefore, for small and medium-sized cassava starch producers, a two-stage hammer crusher crushing method can be used to increase the starch extraction rate and thereby increase the starch yield.

Cassava crushing machine

Cassava crushing machine

Separation stage

The effect of the separation stage on starch yield is the loss of starch during the separation of starch and fibers. In addition to starch, the ground cassava pulp contains impurities such as fibers and proteins, so a separation and refining process is required to remove impurities in cassava starch production line. The centrifugal sieve is used to separate the fiber impurities in the starch. Under the action of gravity and centrifugal force, the fine starch particles in the starch slurry are discharged through the sieve mesh, and the larger fiber impurities cannot pass through the sieve mesh and are taken away by the slag pump. In order to reduce the loss of starch, DOING centrifugal sieve is equipped with an automatic water spraying system. The cassava residue and starch slurry are continuously washed by the flushing water during the separation process to maximize the removal of free starch adsorbed in the slurry and reduce starch loss. On the other hand, the screen mesh size of DOING centrifugal sieve is designed based on our engineer's more than 20 years of experience in starch processing. The size of the screen maximizes the separation of fiber impurities and also reduces starch loss.

Centrifuge sieve

Centrifuge sieve

These are the main factors affecting starch yield in cassava starch production line. With the advancement of technology, starch production has become more and more efficient. For people engaged in starch processing, the best way to get high starch yield is to choose high efficient cassava starch production line equipment. As a manufacturer with decades years of experience in the processing of starch processing equipment, Doing Machinery can tailor cassava starch production line to meet your requirements. If you are interested in starch processing or starch processing equipment, please leave us a message.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others