The common problems of rasper in cassava flour and starch production

The rasper, as the professional crushing equipment for cassava flour and starch production, has the excellent grinding effect, but there are some problems may occur during operation if not careful, such as low grinding efficiency, blade damage, material blockage, etc. Here, Henan Jinrui list the common problems of rasper to help you maximize the benefits of your cassava flour and starch production business.

The most common problem of rasper as a crushing equipment in cassava flour and starch production lines is low grinding efficiency. Because the cassava tubers are too large, if rasper is used directly for crushing, the raw cassava will splash, resulting in insufficient grinding and low grinding efficiency. To solve this problem, Henan Jinrui, a professional cassava processing equipment manufacturer, provides you with an effective solution: before using rasper to crush the cassava, use a cutter to pre-grind the cassava, cut the cassava into small pieces and then put it into rasper for crushing, which effectively avoids raw material loss and improves the grinding efficiency of rasper. The crushing rate can be as high as 98%.

Grinding machine for flour and starch production

Grinding machine for flour and starch production

Blade damage is also a common problem during the operation of rapper. Cassava is hard and may carry other metal impurities. In addition, the blade of rasper is easily damaged when it runs at high speed for a long time. Generally speaking, the blade of rasper should be replaced every half a month. In response to this problem, the rasper provided by Henan Jinrui adopts a bidirectional design, which directly doubles the service life of the blade. In addition, Henan Jinrui recommends that you can configure a demagnetization device, which can effectively absorb the metal impurities carried in cassava, reduce damage to the rasper blade, effectively increase the lifespan of the rasper and save the maintenance cost.

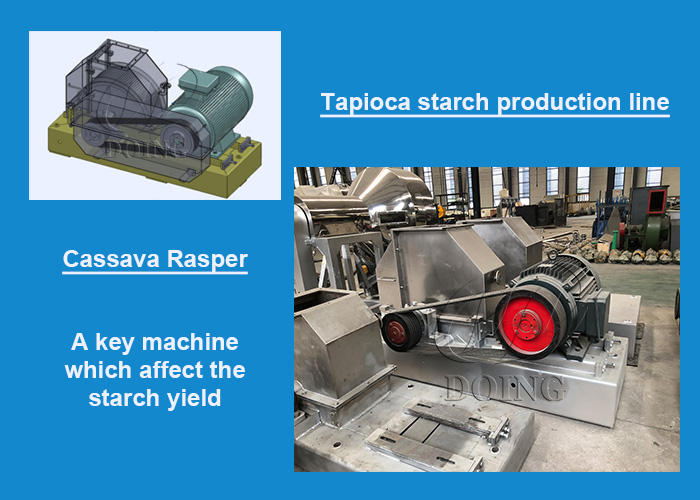

Cassava rasper

Cassava rasper

Cassava is a high-fiber crop. When using rasper to crush cassava, a large amount of fiber is produced, which can easily cause equipment blockage and stop running. This is also an inevitable problem of rasper in the production process of cassava flour and starch. To avoid this problem, you can use rasper manufactured by Henan Jinrui, which is equipped with a long strip bottom net device to effectively filter the fiber in cassava pulp, avoid equipment blockage, and ensure the stable operation of the production line.

Details display of cassava rasper

Details display of cassava rasper

We mentioned above that the life cycle of rasper blades is short, so it is common to replace blades during the production of cassava flour and starch, but it is also a common problem for raspers on the market to replace blades. Henan Jinrui's rasper adopts a modular design and a special slot design, which is convenient for saw blade replacement and effectively solves the problem of blade replacement difficulties.

Henan Jinrui's cassava rasper

Henan Jinrui's cassava rasper

We have just analyzed the common problems of rasper in the production of cassava flour and starch. Understanding the common problems in rasper operation, we can take effective measures to reduce the occurrence of problems and ensure smooth production. The following are some maintenance tips provided by Henan Jinrui for common problems of rasper:

- Regular cleaning: Clean all demagnetization device and bottom net after each use to prevent residue buildup and contamination.

- Timely blade replacement: Timely replacement of damaged blades helps ensure smooth cassava flour and starch production.

- Annual inspection: Have a technician check the machine's structural integrity, alignment, and component wear.

- Choose high-quality equipment: Choosing a high-quality rasper can effectively reduce maintenance costs, for example, using Henan Jinrui's rasper can extend its lifespan.

By addressing these common problems promptly and following proper maintenance practices, cassava rasper can operate efficiently for cassava flour and starch production and prolong the lifespan. In addition to cassava rasper, Henan Jinrui also provide other cassava processing machines for garri, cassava flour and starch production. If you have any demand, welcome to consult us! Henan Jinrui will provide you the high-quality equipment and professional using guidance!

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others