Home > FAQA Guide to High-Yield Cassava Starch Processing Line & Key Equipment in Southeast Asia for Maximizing Profit

A Guide to High-Yield Cassava Starch Processing Line & Key Equipment in Southeast Asia for Maximizing Profit

Southeast Asia is a global leader in cassava production, yet most growers and processors remain at the low-profit stage of selling fresh roots or simply drying them into chips. To significantly increase earnings, the key lies in local processing—specifically, transforming cassava into high-demand tapioca starch. Cassava starch serves not only as a fundamental raw material for numerous food and industrial applications but also as the core ingredient for higher-value products, such as the currently booming tapioca pearls (boba).

Therefore, investing in an efficient, modern cassava starch processing line is a crucial step toward capturing greater value directly from the raw material and accessing lucrative downstream markets. This guide will detail how to select and configure high-yield processing lines and key equipment in Southeast Asia to maximize your profits.

Cassava starch processing equipment

Cassava starch processing equipment

The Foundation of Success: A Complete, High-Yield Cassava Starch Processing Line

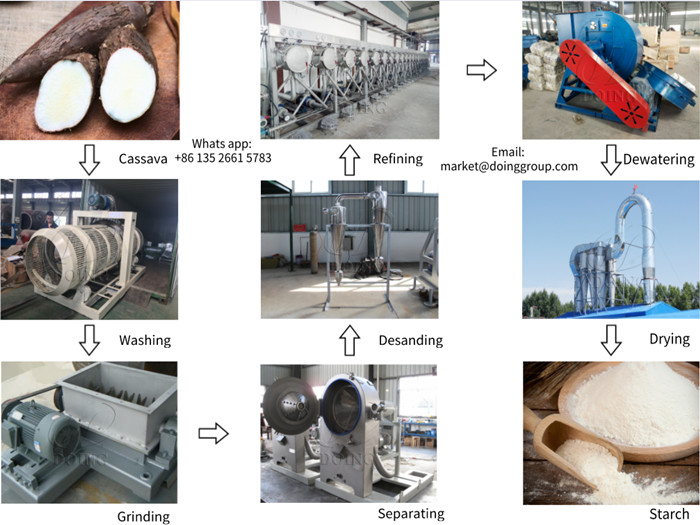

A complete cassava starch processing line is an integrated, often fully automatic system engineered for one core objective: extracting the maximum amount of high-purity starch from raw roots with minimal waste. Unlike simple drying for chips, starch production is a precise, water-intensive extraction and purification process. Its value lies in transforming a perishable, low-margin tuber into a stable, high-demand commodity.

The process follows a dedicated sequence: cleaning & washing, rasping/grating, separation & purification (via centrifuges and hydrocyclones), dewatering, flash drying, and finally cooling & packaging. Each stage's efficiency directly impacts the next, making a calibrated, integrated approach the non-negotiable foundation for maximizing starch yield, ensuring consistent quality, and securing a competitive edge in the Southeast Asian starch market.

Cassava starch processing line

Cassava starch processing line

Key Cassava Starch Processing Equipment for Superior Results

The heart of this high-yield cassava starch processing line lies in its key machinery. Selecting robust, efficient, and appropriately scaled processing equipment is paramount to transforming raw roots into profitable starch products. The following equipment form the essential framework of a modern cassava starch processing line:

Cleaning and Washing Machines: As the first critical stage, this key equipment removes all soil, sand, and impurities. This is non-negotiable for ensuring final product purity and protecting the integrity of all downstream processing equipment. Clean roots are the absolute prerequisite for high-yield cassava processing.

High-Efficiency Rasper: This machine is responsible for the complete disintegration of cassava roots into a fine pulp. Its performance directly determines the starch release rate, making it one of the most vital pieces of equipment for maximizing extraction and overall starch yield.

Centrifuge Sieve and Hydrocyclone Station: This equipment forms the core of modern cassava starch processing line. It expertly separates pure starch from fiber, protein, and other soluble impurities. A multi-stage hydrocyclone station is essential for achieving the high purity and recovery rates required for premium-grade starch.

Henan Jinrui cassava starch processing machine

Henan Jinrui cassava starch processing machine

Dewatering and Drying Equipment: To preserve the extracted starch, efficient moisture removal is critical. A peeler centrifuge performs efficient dewatering, which is then followed by a flash dryer that rapidly reduces moisture to a stable, low level. This key equipment prevents spoilage, ensures long shelf life, and secures the value obtained from the high-yield processing stages.

Milling, Sieving, and Automated Packing: The final phase prepares the product for the market. Precision milling ensures a uniform starch particle size, followed by sieving for consistency. Automated packaging presents a professional, market-ready product that commands the best price, finalizing the journey to maximize cassava profit.

By implementing the high-yield cassava starch processing line and key equipment outlined in this guide, Southeast Asian processors can transform the operations from volume-based to value-driven. This upgrade is the definitive pathway to maximizing your profit in the competitive starch market. Want to begin this high profit cassava starch investment, contact Henan Jinrui for a detailed consultation and equipment proposal.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour