Home > FAQTraditional Sun-Drying vs. Machine Drying: How to choose the drying method for cassava starch production?

Traditional Sun-Drying vs. Machine Drying: How to choose the drying method for cassava starch production?

Cassava, a vital global staple, relies heavily on efficient starch extraction. The final drying stage is critical, determining starch quality, shelf life, and economic viability. Producers face a fundamental choice: harness the power of the sun or leverage modern machine drying. Next, Henan Jinrui will introduce each of them, aiming to give support for your cassava starch production.

cassava starch

cassava starch

1. Traditional Cassava Starch Drying Method: Natural Sun-Drying

Process: Wet cassava starch cake (typically 35-45% moisture) is spread thinly (1-2 cm) on clean, raised concrete platforms, plastic sheets, or tarpaulins under direct sunlight. Regular turning ensures even drying over several days (2-5 days, heavily weather-dependent).

Advantages:

Low Capital Cost: Minimal investment needed (drying beds/tarps). Ideal for small-scale cassava starch producers or startups.

Zero Energy Cost: Relies solely on solar energy, significantly reducing operational expenses.

Simplicity: Requires minimal technical expertise to operate.

Gentle (Potentially): Low temperatures generally avoid starch gelatinization if managed carefully.

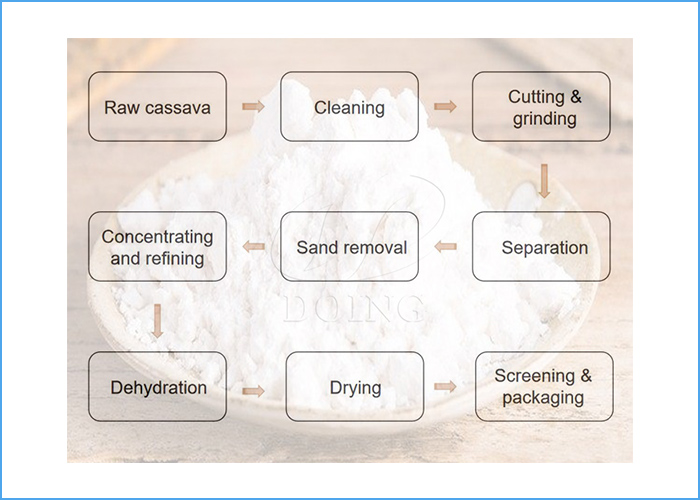

cassava starch production flow

cassava starch production flow

Disadvantages:

Weather Dependency: Highly vulnerable to rain, high humidity, cloudy days, and dust. Cassava starch production halts during bad weather, causing delays and spoilage risk.

Slow Drying: Takes multiple days, increasing exposure time to risks.

Contamination Risk: High exposure to dust, insects, birds, rodents, and microorganisms (fungi, bacteria). Significant risk of product contamination and mycotoxin development if moisture lingers.

Inconsistent Quality: Uneven drying leads to variations in moisture content, color (yellowing), and purity within and between batches.

Labor Intensive: Requires significant manual labor for spreading, turning, and gathering.

Space Intensive: Needs large, dedicated, clean drying areas.

Limited Scale & Control: Difficult to scale up significantly and offers no control over drying parameters.

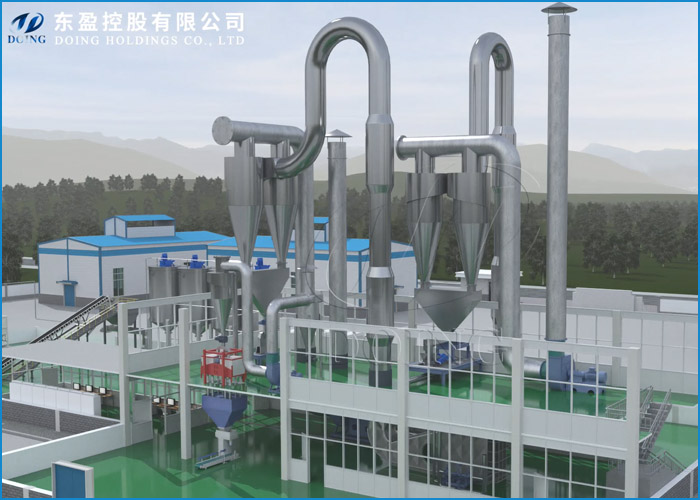

2. Modern Flash Dryer Drying: Precision and Power

Process: Wet cassava starch is fed into mechanical flash dryers. Heated air (generated by electricity) rapidly evaporates moisture in minutes or hours, reducing it to 12-14%.

two-staged cassava powder flash dryer

two-staged cassava powder flash dryer

Advantages:

Weather Independence: Production continues 24/7/365 regardless of external conditions.

Speed: Drying is completed rapidly (1-2 seconds ), minimizing exposure time.

Consistent Quality: Precise control over temperature, airflow, and residence time ensures uniform moisture content, brightness, and purity. Ideal for high-quality cassava starch drying.

Hygiene & Safety: Enclosed system minimizes risks of dust, insect, rodent, and microbial contamination.

Space Efficient: Requires much less physical footprint than sun-drying for equivalent output.

Process Control: Allows optimization for specific cassava starch properties.

flash dryer and its details

flash dryer and its details

Disadvantages:

High Capital Cost: Significant investment required for dryer purchase, installation, and auxiliary equipment (air heaters, fans, ducts, cyclones), more suitable for scale cassava starch production.

High Operating Cost: Substantial energy costs (fuel/electricity) and maintenance costs.

Technical Complexity: Requires skilled operators and maintenance personnel.

Risk of Overheating: Improper control can lead to localized overheating, causing starch gelatinization (reducing solubility, increasing viscosity) or browning (caramelization), degrading quality.

Energy Dependency: Vulnerable to fuel price fluctuations and power outages without backup.

All in all, if you are a small cassava starch setup, it is economic for you to dry the starch by sunlight. While if you a large starch producer, it is wise for you to install a flash dryer. We, Henan Jinrui, manufacture cassava machines since 2011and now have a branch office in Nigeria. No matter you want to purchase a single cassava starch flash dryer or a complete starch production line, you can discuss with us!

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Other:

- What is the final product you want to produce?

- Chips

- Flour

- Starch

- What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Other:

- What is your planned capacity for final product?

- <1 ton per day

- 1 ton per day

- 2 tons per day

- 3 tons per day

- 3-10 tons per da

- 10-20 tons per day

- >20 tons per day

- What is the usage of your cassava chips?

- Food usage (like fried chips, flour)

- Industrial usage (like animal feeds, ethanol)

- What is your planned capacity for final product?

- <5 ton per hour

- 5-10 tons per hour

- >10 tons per hour

- What is your planned capacity for final product?

- <500 kg per hour

- 0.5-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour

- What is your planned capacity for final product?

- <300 kg per hour

- 300-1000 kg per hour

- 1-5 ton per hour

- 5-10 ton per hour

- >10 ton per hour