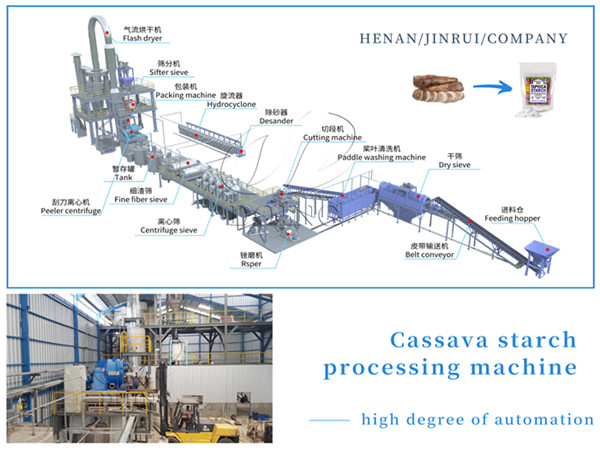

The fully automatic cassava starch production line offers superior efficiency, quality, and cost-effectiveness. Its automation, high extraction rate, and eco-friendly design make it ideal for large-scale starch producers....

In this article, we will introduce the plate-frame filter press, the professional dehydration equipment used for cassava flour processing, exploring the working principle and application of plate-frame filter press....

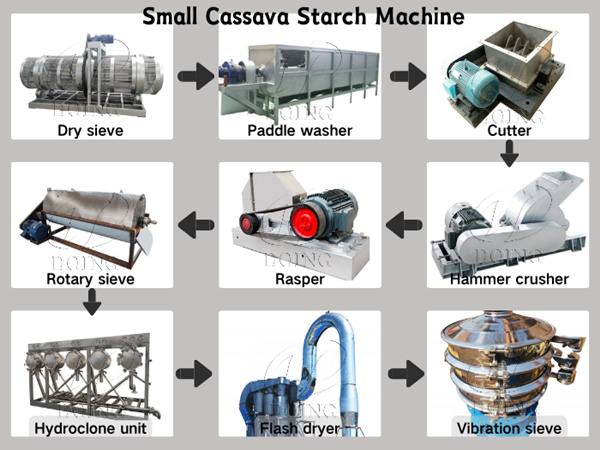

For small-scale cassava farmer or entrepreneur with limited capital, when choosing cassava starch processing machine, you should consider the capacity, energy efficiency, types, and supplier....

The high quality cassava flour usually has low moisture content and can be stored for a long time! Generally, the moisture content of cassava flour processed by Henan Jinrui cassava processing machine can reach 12%, reaching the high quality standard!...

Starch purification machinery mainly refers to centrifuge sieve and hydrocyclone station, which directly influences the grade of final starch....

There are 2 methods for cassava flour production, wet method and dry method. However, do you know the distinction of cassava flour produced by dry and wet methods? Let's unlock the differences, from processing steps to products application!...

12-stage hydrocyclone station is the best configuration level in starch production, due to its higher protein removal rate, optimal water usage efficiency, and balanced quality, yield, and cost....

Profitability of setting up a potato starch processing factory in India lies in its scalable raw material access, diversified demand, and policy tailwinds....

Cassava flour and maize flour both is the common staple, but there are some differences between cassava flour and maize flour. Here, Henan Jinrui will explore the differences in detailed, from processing methods to product application....

The rasper is the common grinder in cassava flour and starch production. Understanding the common problems during rasper running can effectively ensure the stable operation of production line and reduce the maintenance cost....

To ensure the stable operation of cassava starch processing equipment, you should make regular maintenance and inspections, train operators and standardize procedures, and monitor the automatic production line,etc....

In Africa, many cassavas are planted and mature every year. Do you know how to make money from planting and processing cassava? In this article, Henan Jinrui will give you a complete guide on how to benefit from cassava planting and processing....