How to make starch from cassava?

The cassava starch production line adopts the wet processing of starch production without any additive. The whole cassava starch production line smoothly produces quality fine starch, and it takes less than one hour from feeding to dry starch. The automatic sealing system ensures the smooth process of the whole production line. But how to make starch from cassava? Then we will explain this question for you.

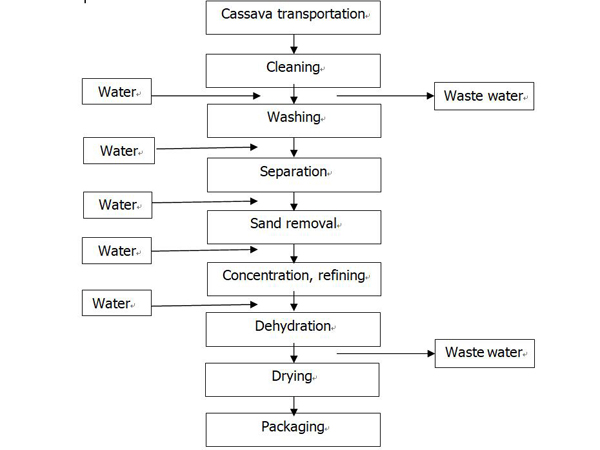

Here are the complete production process for how to make starch from cassava

raw materials transportation-cleaning-washing-crushing-separation-sand removal-concentration and refining-vacuum dehydration-air flow drying-packaging the finished product.

Cassava starch making process

Cassava starch making process

1. Transportation: After the cassava is transported to the workshop, a series of cleaning work, such as stone removal and mud removal, need be carried out to avoid affecting the normal operation of the equipment for how to make starch from cassava, affecting product quality and safety production.

2.Cleaning: For the process of how to make starch from cassava, cleaning is the basic step which has an important influence on the subsequent processing procedure. The main purpose is to remove the sediment from the outer skin layer of the cassava root. The cleaner the cleaning, the better the quality of the starch.

3.Washing: Washing is also the basis for ensuring the quality of the starch for how to make starch from cassava. Its main function is to wash away the sand, dirt and epidermis of the cassava roots.

Cassava washing machine

Cassava washing machine

4.Crushing: Crushing is the most important procedure for how to make starch from cassava for it determines the starch yield. The purpose of crushing is to destroy the structure of cassava, so that the tiny starch granules can be smoothly separated from the cassava roots. Starch released from cells is called free starch, and the more free starch released, the higher starch yield. DOING rasper is a high crushing coefficient machine which can achieve a breaking rate more than 94%.

5.Separation: Separation is mainly for separating fibers out of starch slurry for the process of how to make starch from cassava. Centrifuge sieve and fine fiber sieve are used for the purpose. Multiple screening or countercurrent washing processes are commonly used to achieve better separation effect. It is required that after separation, the fiber impurity content of the starch slurry is less than 0.05%.

Cassava starch separating machine

Cassava starch separating machine

6.Desanding: The main purpose of desanding for how to make starch from cassava is to remove sand from starch slurry so as to improve starch taste and quality. Due to the specific gravity of sand is greater than that of water and starch particles. The cassava starch processing plant uses desander to remove sand according to the principle of gravity separation.

7.Concentration and refining: Concentration and refining process for how to make starch from cassava is used to separate protein, cell sap and other impurities from starch slurry, so as to achieve the purpose of washing, refining and concentration of starch milk. Hydrocyclone station is used for this process. The starch milk enters the 24 stages concentrated hydrocyclone washing unit, and the process water is pumped in from the other end of the hydrocyclone station to wash the starch by reverse flow.

8.Dehydrating: After the refining process, the starch slurry still contains a lot of water, so it need to be dehydrated before drying. Peeler centrifuge is often used for dewatering. The moisture content of wet starch after dehydration is required to be lower than 38% for how to make starch from cassava.

Cassava starch dehydrating machine

Cassava starch dehydrating machine

9.Drying and packing: Then is the last step for how to make starch from cassava. The dried starch cake is transported to the feed port of the air drying machine through the conveyor belt. Flash dryer takes use of high speed hot air to dry starch. After drying, starch is separated from air in a set of cyclone separators. And the collected starch is transported to semi-automatic packaging machine to be packaged into 25kg or 50kg finished products. The specification of packing can be designed according to requirements.

In conclusion, the above is the detail introduction of how to make starch from cassava. As a professional cassava starch processing machine manufacturer, Doing Company can provide complete set starch processing equipment design, installation and debugging, workers training one-stop service system.

-

Cel/WhatsApp: +8613526615783

Cel/WhatsApp: +8613526615783

-

Phone: +86 371 5677 1822

Phone: +86 371 5677 1822

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

-

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Address: Room 1408,14th Floor,Building 9,No.133 Yaozhai Road,Jinshui District,Zhengzhou City,Henan Province,China

Related Projects

Contact Us

Want to know more about our products or services? Fill out the contact form below, and we’ll to get back to you and you will get the price list. Please also feel free to contact us by email or phone.( * Denotes a required field).

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I Just learning

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others